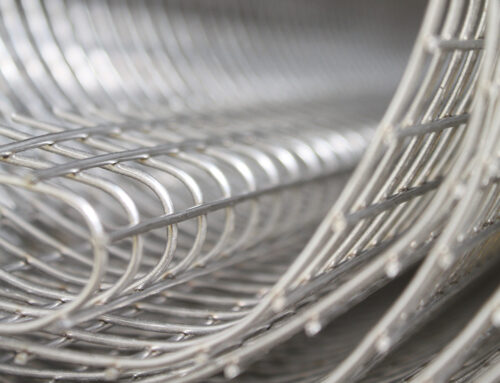

One material that has become indispensable in industrial design and construction is wire mesh. However, when standard solutions fall short of unique project demands, bespoke wire mesh fabrications step in to provide the perfect fit.

At Wire Mesh Fabs, our expertise in crafting custom solutions ensures that every project—from architectural installations to heavy-duty industrial applications—is executed with precision and durability. Read on to discover why bespoke wire mesh solutions are an essential component of modern industrial projects.

1. Customised to Meet Unique Project Specifications

No two industrial projects are identical, and that’s what makes bespoke wire mesh so valuable. Standard mesh products often lack the flexibility required to address the diverse demands of industrial design. Bespoke solutions, by contrast, allow clients to specify exact dimensions, shapes, and materials, ensuring the product performs flawlessly in its intended application.

Perfect Fit for Complex Designs

Many industrial environments, such as chemical plants or automated warehouses, feature complex structures requiring precise mesh solutions. For example, protective guards for machinery or enclosures for hazardous areas must fit seamlessly while adhering to safety regulations. Bespoke wire mesh allows for customisation of hole size, material thickness, and panel dimensions to perfectly fit these intricate designs.

Adaptability Across Industries

Bespoke wire mesh caters to a wide range of industries, from food processing and construction to aerospace and medical sectors. For example, high-grade stainless steel wire mesh is widely used for industrial decontamination systems, where hygiene is paramount. Customisation guarantees the mesh meets strict standards specific to each sector.

2. Uncompromising Durability

Durability is non-negotiable in industrial settings, where equipment and materials are exposed to harsh environments and heavy usage. Bespoke wire mesh solutions provide the strength and resilience necessary for long-term performance, even in the most challenging conditions.

High-Quality Materials

Bespoke mesh products are typically fabricated from durable materials such as stainless steel, galvanised steel, or coated alloys. These materials are selected not only for their strength but also for their resistance to corrosion, heat, and chemicals. For instance, stainless steel mesh is ideal for outdoor applications where exposure to rain and salt air could compromise lesser materials.

Longevity Reduces Costs

Investing in high-quality, custom-fabricated wire mesh ensures longevity, reducing the need for frequent replacements and costly downtime. This makes bespoke solutions a cost-effective choice in the long run, particularly for industrial projects with demanding operational schedules.

3. Versatility in Design and Applications

One of the standout features of bespoke wire mesh solutions is their versatility. They can be tailored to serve simple functions, such as fencing and partitions, or more complex roles, like filtration and structural reinforcement.

Architectural Innovation

In addition to industrial uses, wire mesh has gained popularity in architectural applications. It is used for stylish balustrades, stairwell infills, and even decorative façades. Bespoke designs allow architects and builders to incorporate mesh in innovative ways, blending functionality with aesthetic appeal.

Security Applications

Security is a significant concern in industrial and commercial environments. Wire mesh can be customised to create robust fencing systems, window guards, and machine guards that protect installations from unauthorised access while maintaining ventilation and visibility. Bespoke fabrication ensures the product meets specific security standards, whether it is for high-security data centres or warehouse storage.

Specialist Uses

Specialist applications often require unique solutions that standard mesh cannot provide. For example, wire mesh trays are used in food processing to store and handle items like baked goods or smoked salmon. These trays must be customised to exact specifications and food safety standards, such as those outlined by the Food Standards Agency in the UK.

4. Eco-Friendly and Sustainable Solutions

Industrial projects today must align with increasing demands for sustainable practices and materials. Bespoke wire mesh offers several eco-friendly advantages over traditional alternatives, helping businesses meet sustainability goals without compromising on performance.

Efficient Material Use

By tailoring the dimensions and specifications of wire mesh to the project, bespoke fabrication minimises material waste, making it inherently more efficient than off-the-shelf solutions. Unlike bulk standard products, custom designs ensure you aren’t left with surplus materials that add to waste or unnecessary expenditure.

Recyclability

Wire mesh is made primarily from recyclable materials such as stainless steel, making it an environmentally friendly option. At the end of its life cycle, the mesh can be repurposed, reducing the impact on landfill sites and supporting circular economy principles.

5. Collaborative Design for Optimal Results

Working with a professional wire mesh fabrication company ensures that every solution is designed with the client’s exact needs in mind. From the initial consultation to the final delivery, expert teams guide customers through the entire design and manufacturing process.

Consultative Approach

At Wire Mesh Fabs, we take a collaborative approach to fabrication, starting with detailed project consultations. Whether you need intricate filtration mesh or durable security panels, we work closely with you to understand your requirements, recommend the best materials, and ensure all industry regulations are met.

Prototyping for Precision

Creating prototypes during the design phase allows clients to test the product’s fit and performance before full-scale production. This ensures the final product is perfectly suited to its intended role, reducing the risk of errors and costly adjustments.

Bespoke Tools and Machinery

Specialist projects often require equally specialist manufacturing tools. At Wire Mesh Fabs, we use state-of-the-art equipment to fabricate custom wire mesh, ensuring precise results every time.

Choose Wire Mesh Fabs for Your Bespoke Solutions

For over four decades, Wire Mesh Fabs has been a trusted name in the UK for high-quality wire mesh solutions. Our dedication to craftsmanship and innovation ensures we deliver made-to-order fabrications tailored to the unique demands of industrial projects. From durable materials to eco-conscious designs, we provide solutions that enhance efficiency, safety, and long-term value.

Final Thoughts

Bespoke wire mesh solutions offer unparalleled versatility, durability, and precision, making them essential for modern industrial projects. Whether you’re upgrading security, supporting heavy machinery, or improving aesthetics, custom-fabricated mesh fits seamlessly into any project while meeting the highest standards of quality.

Contact Wire Mesh Fabs today to discover how our bespoke solutions can elevate your next industrial project. Together, we’ll design and fabricate wire mesh tailored to your exact needs, setting the standard for excellence in the UK industry.