From its role in industrial screening processes to architectural design, woven mesh offers a unique combination of flexibility and strength that makes it indispensable across a wide range of sectors.

But what exactly gives woven mesh its strength? And how does this differ from other types of mesh products? In this article, we explore the qualities that make woven mesh such a robust and reliable material, and why it remains a trusted solution for demanding applications.

What Is Woven Mesh?

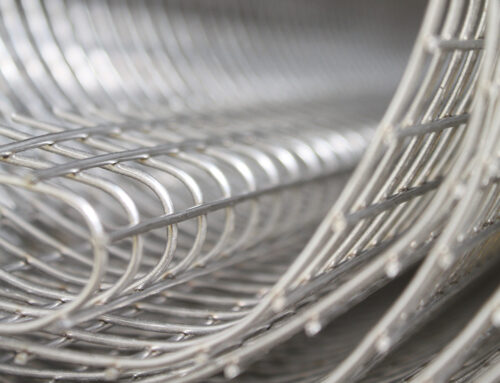

Woven mesh is created by interlacing metal wires in an over-and-under pattern, much like fabric. This method of weaving allows the mesh to remain flexible while retaining impressive tensile strength. It is typically made from materials such as:

-

Stainless steel

-

Mild steel

-

Galvanised steel

-

Brass or copper (for specialist applications)

At Wire Mesh Fabrications, we supply high-quality woven mesh that can be tailored to your specific application, offering options in mesh count, wire thickness, and material type.

What Makes Woven Mesh Strong?

The strength of woven mesh comes down to several key factors:

1. Material Quality

Using high-grade metals such as 304 or 316 stainless steel ensures corrosion resistance and long-term performance, even in harsh environments. Stainless steel woven mesh, for instance, is highly resistant to heat, chemicals and abrasion – making it ideal for filtration, sieving, and protection.

2. Wire Diameter

The thicker the wire, the greater the mesh’s tensile strength and resistance to impact or deformation. While finer wires are used in detailed filtration or precision sieving, thicker wires are chosen for applications like safety guards, fencing, and heavy-duty screens.

3. Weave Pattern

The way wires are interwoven directly affects the mesh’s durability and flexibility. Common weave types include:

-

Plain Weave – The simplest and most common, offering a balanced structure for general-purpose use.

-

Twill Weave – Each wire passes over two and under two, increasing flexibility while maintaining strength.

-

Dutch Weave – Used for fine filtration; combines smaller warp wires and larger weft wires for high strength and density.

4. Tension and Stability

Unlike welded mesh, woven mesh does not rely on spot welds for its integrity. Instead, its strength is derived from the tension created by the interwoven wires. This gives woven mesh a unique combination of flexibility and form-retaining strength, especially valuable in applications where the mesh must adapt to dynamic forces or curved surfaces.

Where Strength Matters: Applications of Woven Mesh

Because of its strength and durability, woven mesh is used in a wide range of applications that demand both precision and resilience:

● Filtration and Sieving

Used extensively in the chemical, food, pharmaceutical, and mining industries, woven mesh provides reliable particle separation while withstanding pressure and mechanical wear.

● Safety and Protection Screens

In machinery guards, balustrades, or architectural barriers, woven mesh offers a combination of transparency, ventilation, and robust physical protection.

● Fencing and Enclosures

Where visual access and airflow are needed – such as in aviaries, animal enclosures, or perimeter fencing – woven mesh is a strong and weather-resistant solution.

● Construction and Infrastructure

Woven mesh is ideal for reinforcement, ventilation grilles, and even decorative cladding, bringing both strength and style to modern structures.

● Aerospace and Automotive

In high-precision sectors, woven mesh is used for filtration systems, ventilation screens, and shielding components, where material reliability is paramount.

The Benefits of Choosing Woven Mesh

Here are some of the key reasons professionals across the UK rely on woven mesh:

-

High tensile strength – Withstands impact and heavy use

-

Corrosion resistance – Especially when made from stainless steel

-

Precision construction – Suitable for fine filtration and sieving

-

Flexible yet durable – Adapts to form without losing integrity

-

Wide range of specifications – Tailored to your exact needs

Why Choose Wire Mesh Fabrications?

At Wire Mesh Fabrications, we supply bespoke woven mesh products crafted to the highest standards. Whether you require mesh for industrial screening, protective guarding, or architectural design, we provide:

-

A wide selection of materials and weave patterns

-

Custom mesh counts and wire gauges

-

Technical support for demanding applications

-

Fast and reliable delivery across the UK

With decades of experience in supplying woven mesh to sectors including engineering, architecture, agriculture and processing, we are the trusted partner for quality and consistency.

Final Thoughts

The strength behind woven mesh lies in its careful construction, high-quality materials, and engineered weave patterns. From filtration systems to security fencing, woven mesh continues to offer the performance and resilience needed across numerous industries.

If you’re seeking a solution that combines durability, versatility, and precision, woven mesh could be the perfect fit. Discover more about our woven mesh range here or contact our knowledgeable team for expert advice.