Perforated metal sheets are an increasingly popular material in both industrial and architectural applications, prized for their strength, versatility, and sleek appearance. But beyond their aesthetic appeal, one of the most valuable attributes of perforated metal is its ability to enhance airflow and ventilation.

Whether used in commercial buildings, manufacturing facilities, transport infrastructure or even home installations, perforated metal sheets offer a practical solution for managing airflow while maintaining structural integrity and visual appeal. In this article, we explore how perforated metal sheets improve ventilation and why they are the preferred choice across multiple sectors.

What Are Perforated Metal Sheets?

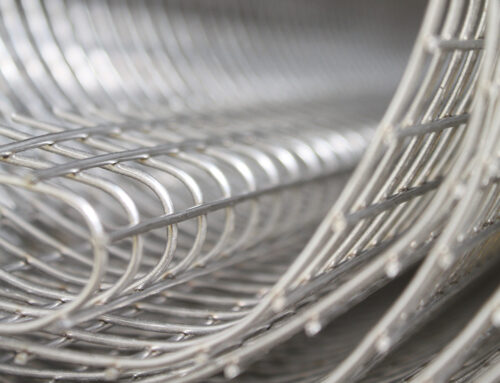

Perforated metal sheets are flat metal panels that have been mechanically punched with a pattern of holes, slots or other shapes. These perforations are precisely engineered to achieve specific open areas, airflow rates, and acoustic or visual effects.

Common materials include:

-

Mild steel

-

Stainless steel

-

Aluminium

-

Galvanised steel

At Wire Mesh Fabrications, we supply a wide range of perforated metal sheets, tailored to your project’s ventilation, durability, and design requirements.

The Role of Perforated Metal in Ventilation

Ventilation is crucial in almost every environment – from office buildings and factories to underground car parks and machinery enclosures. Without sufficient airflow, spaces can become uncomfortable, unsafe, or even hazardous.

Here’s how perforated metal supports effective ventilation:

1. Promotes Natural Airflow

Perforated metal allows air to pass through freely while acting as a physical barrier. By adjusting the open area percentage (the total space occupied by holes vs. solid metal), designers can control the amount of airflow through a surface. This makes it easy to regulate passive ventilation, especially in enclosed or semi-open spaces.

Applications include:

-

External cladding with airflow gaps

-

Soffit vents

-

Louvered facades

-

Plant room enclosures

2. Reduces Overheating

In environments where machinery or electronics generate heat – such as data centres, manufacturing plants, and mechanical rooms – maintaining airflow is vital to prevent overheating. Perforated metal panels used in enclosures, racks or ventilation ducts help to dissipate heat without sacrificing security or support.

This makes perforated metal a go-to choice for:

-

Server cabinet fronts

-

Machine housing panels

-

Vent covers and grilles

3. Controls Moisture and Condensation

Airflow is essential not just for temperature, but also for moisture control. Stagnant air can lead to condensation, which may result in damp, corrosion or mould. Perforated metal sheets, particularly in galvanised or stainless steel, allow air to circulate while protecting the underlying structure or components.

This is particularly useful in:

-

Agricultural storage buildings

-

Underground parking structures

-

Greenhouses and horticultural environments

4. Supports Mechanical Ventilation Systems

In systems where fans or air handling units (AHUs) are used, perforated metal can act as duct covers, diffusers or intake grilles, allowing mechanical airflow while keeping debris and insects out. The rigidity of the metal also means that it holds up better than plastic alternatives over time, particularly in high-traffic or industrial environments.

5. Improves Energy Efficiency

By enhancing natural ventilation, buildings can reduce reliance on mechanical cooling and heating systems, leading to better energy efficiency. Strategically installed perforated panels – such as solar shading screens and rain screens – allow warm air to escape and fresh air to enter, naturally regulating indoor temperatures.

This is particularly valuable in:

-

Sustainable architecture

-

LEED/BREEAM-accredited developments

-

Eco-conscious refurbishments

Design Flexibility

Perforated metal is not just about function – it offers significant design flexibility too. You can select from a variety of hole shapes (round, square, hexagonal, slotted), patterns, and finishes. This allows architects and designers to balance airflow requirements with branding, aesthetics and privacy needs.

Popular uses include:

-

Decorative façade panels

-

Office ceiling tiles

-

Acoustic ventilation screens

-

Privacy barriers with airflow

Why Choose Perforated Metal from Wire Mesh Fabrications?

At Wire Mesh Fabrications, we specialise in custom perforated metal sheet solutions that meet precise ventilation, structural and visual requirements. We provide:

-

A wide range of materials, patterns and finishes

-

Bespoke cutting and fabrication

-

Technical support on airflow and strength requirements

-

Reliable delivery and UK-wide service

Our perforated sheets are suitable for construction, manufacturing, infrastructure, agriculture, and design-led projects, all manufactured to high standards with attention to detail.

Summary: The Smart Choice for Ventilation

Perforated metal sheets offer an unbeatable combination of airflow performance, structural reliability and visual appeal. Whether you’re ventilating an equipment enclosure, improving airflow in a commercial property, or designing a breathable building façade, perforated metal provides a long-lasting and adaptable solution.

If you’re planning a project where airflow and ventilation are key, explore our perforated metal sheet range here or contact our expert team for advice on selecting the right product for your specific needs.