Industries across the UK rely on innovative technologies and materials to meet their unique requirements, and custom wire mesh is at the forefront of these solutions. Whether used in architecture, manufacturing, security, or even medical applications, wire mesh is one of the most dependable and adaptable materials available today. However, to achieve its full potential, a customised approach that takes every detail into account is essential.

From the initial design phase through fabrication and installation, bespoke wire mesh production ensures that every specification is met with precision. Here’s an in-depth look at how the design-to-fabrication process supports specialist applications and why tailored mesh is indispensable for modern projects.

Why Choose Custom Wire Mesh?

Off-the-shelf mesh products often fail to address the specific requirements of specialist industries. Whether it’s due to unusual dimensions, adverse environmental conditions, or enhanced safety regulations, standard solutions can fall short. This is when custom wire mesh comes into play.

Tailored mesh allows for the exact specification of size, material, weave density, and finish. This means it can be designed to perform flawlessly no matter how challenging the application may be. With bespoke fabrication, industries can optimise safety, efficiency, and durability for their unique needs.

The Design Process

Every successful custom wire mesh project begins with a detailed and collaborative design phase. This is where the groundwork is laid to ensure the final product meets all functional and aesthetic requirements.

Understanding the Application

Before any physical work begins, it’s crucial to fully understand the application in question. Is the mesh needed for filtration, ventilation, security, or structural support? Each of these uses will have different requirements, such as strength, permeability, or impact resistance.

For instance, medical sterilisation trays need fine woven mesh to retain small surgical instruments while maintaining hygiene standards. On the other hand, anti-climb fences for security purposes require welded mesh that is robust and tamper-proof.

Material Selection

Choosing the right material is key to the mesh’s performance. Wire mesh can be crafted from a variety of metals, including stainless steel, galvanised steel, and aluminium. Specific materials are chosen based on their durability, resistance to environmental conditions, and suitability for a given industry.

For instance, stainless steel is preferred for food and medical applications due to its non-reactive, corrosion-resistant properties. Galvanised steel, on the other hand, is often used in outdoor fencing or industrial enclosures because of its ability to withstand harsh elements.

Custom Specifications

Every detail of the mesh is meticulously planned, from the gauge (wire thickness) to the aperture size (gap between wires) and overall dimensions. These factors determine the strength, flexibility, and intended function of the wire mesh.

Prototyping and Testing

For projects with complex requirements, prototyping ensures the design performs as intended. A prototype allows for thorough testing in its intended environment, highlighting any necessary adjustments before full-scale fabrication begins. This stage is vital for high-stakes applications such as aerospace or chemical processing.

The Fabrication Process

Once the design is finalised, the fabrication process transforms the concept into a fully realised product. Advanced machinery and skilled craftsmanship come together to deliver precise and reliable results.

Cutting and Shaping

State-of-the-art equipment ensures the mesh is cut to precise measurements. CNC machining is often employed to achieve accuracy, whether producing straight panels, curved forms, or irregular shapes for specialist uses.

Weaving or Welding the Mesh

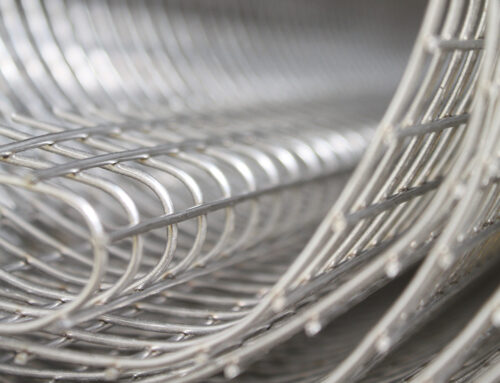

Wire mesh can either be woven or welded, and the choice depends on its intended application.

- Woven Mesh: This method involves interlacing wires in a specific pattern to achieve varying levels of strength and flexibility. It’s ideal for applications like filtration or decorative facades.

- Welded Mesh: Wires are welded at their intersections, creating a rigid and durable structure. Welded mesh is commonly used for security fencing, machine guards, and heavy-duty enclosures.

Treatments and Finishes

Many projects require additional treatments to enhance the mesh’s durability or appearance. This might include galvanising, powder coating, or anodising to improve corrosion resistance, longevity, and aesthetic appeal.

Quality Assurance

No custom wire mesh leaves the fabrication facility without undergoing rigorous quality checks. Tests for strength, durability, and dimensional accuracy ensure the product is ready for its intended use. Precision is non-negotiable, particularly for safety-critical applications in industries like aerospace or infrastructure.

Supporting Specialist Applications

From design to final product, bespoke wire mesh supports a vast range of specialist applications across industries. Here’s how it shines in key sectors.

Architecture

Wire mesh elevates architectural projects, offering both function and beauty. In stairwell infills, mesh ensures safety while maintaining a minimalist aesthetic. For building façades, architects use wire mesh to add visual intrigue and control sunlight.

Custom fabrication allows these designs to perfectly integrate into existing structures while meeting technical demands such as weight support and weather resistance.

Industrial Applications

Industries like oil and gas, manufacturing, and chemicals depend on wire mesh for safety, filtration, and reinforcement. Custom designs are essential for extreme environments, whether perforated panels for cooling systems or reinforced structures for heavy-duty support.

Medical Use

Sterilisation, organisation, and durability are crucial in the medical sector. Bespoke trays and baskets made from sanitary-grade stainless steel meet these needs perfectly. Mesh used in hospital settings must adhere to rigorous hygiene standards, making customisation a must.

Security Systems

High-security facilities use custom wire mesh designs for fencing, gates, and enclosures. Anti-climb mesh panels are fabricated to resist tampering, intrusion, and weathering, making them a key component in site safety.

Why Custom Wire Mesh from Wire Mesh Fabs?

At Wire Mesh Fabs, we specialise in designing and fabricating bespoke wire mesh solutions tailored to your specific needs. With over 40 years of experience, our team understands the importance of precision and quality in specialist applications.

Our Advantages:

- Custom consultation, design, and prototyping services.

- Advanced manufacturing machinery for accuracy.

- High-quality materials sourced within the UK.

From initial consultation to final delivery, we’re committed to exceeding your expectations with innovative solutions built for efficiency, safety, and durability.

Final Thoughts

Bespoke wire mesh bridges the gap between design and functionality, supporting specialist applications in industries that demand nothing less than excellence. From architectural infills to industrial filtration systems, the ability to customise mesh ensures the final product is perfectly suited to its purpose.

Whether you’re envisioning a sleek façade or need heavy-duty safety enclosures, custom wire mesh is the solution that brings your project to life. Contact Wire Mesh Fabs today to explore our design-to-fabrication services and experience the tailored solutions that set us apart in the UK.