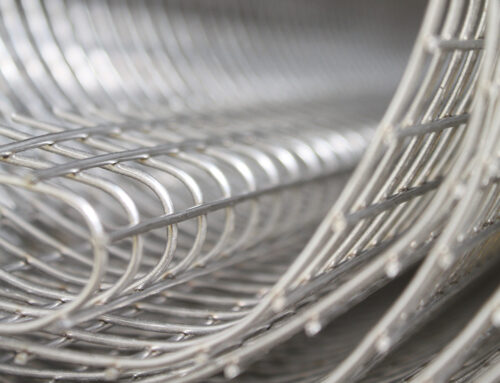

Wire mesh is one of the most adaptable materials used in modern construction and industrial applications. Highly durable, versatile, and customisable, it’s a favourite amongst architects, security specialists, and manufacturers across the UK. From sleek architectural accents to robust security fencing and precision-driven industrial applications, wire mesh offers a blend of style and utility that few materials can rival.

If you’re wondering how one material can cater to such a broad range of needs, this guide explores the unique capabilities of wire mesh across architecture, security, and manufacturing.

Applications in Architecture

Wire mesh is redefining architectural design, bridging the gap between functionality and artistry. Its versatility makes it a prized choice for creating visually appealing but practical solutions.

Decorative Features

Wire mesh is often used to add texture and interest to buildings. For example, architects use it to create façades, balustrades, and partitions that combine aesthetic appeal with durability. One of the key benefits of wire mesh in architecture is its ability to introduce transparency and depth while maintaining structural integrity.

Materials such as stainless steel and brass are popular choices for architectural mesh, offering a modern and polished finish that resists corrosion. Designers may even choose custom colours or patterns to enhance a building’s aesthetics further.

Shading and Ventilation

For environmentally conscious designs, wire mesh contributes to energy efficiency by acting as a passive shading system. These installations help reduce internal temperatures without blocking natural light entirely, making buildings more sustainable. Mesh panels are frequently used in office buildings, parking structures, and stadiums to maximise air flow while maintaining sun protection.

Structural Support

Wire mesh shines in functional roles as well. It’s widely utilised for stairwell infills, mezzanine flooring, and safety barriers in multi-level buildings. These materials are strong enough to provide support while maintaining a lightweight and minimalist appearance, which aligns beautifully with modern design principles.

Enhancing Security with Wire Mesh

Security is one of the most vital aspects addressed by wire mesh. Its strength and durability make it an ideal choice for various protective applications, from simple barriers to specialist systems for high-risk environments.

Perimeter Fencing

Wire mesh fencing offers a robust and long-lasting solution for securing sites, industrial premises, and commercial properties. Options range from galvanised steel fences for general use to anti-climb mesh systems designed for maximum security facilities like prisons and data centres.

What sets wire mesh fencing apart is its ability to provide security without obstructing visibility. This ensures that surveillance systems and guard operations are not hindered, offering an added layer of protection.

Window Guards and Enclosures

Wire mesh is ideal for safeguarding vulnerable points such as windows, skylights, and air vents. The material can be custom-fabricated into shapes and sizes that fit seamlessly into existing structures, offering a visually neutral appearance while preventing unauthorised access.

For industries like retail or hospitality, bespoke wire mesh window guards serve as an unobtrusive security feature, particularly after business hours.

Machine Guarding

Industrial environments benefit significantly from wire mesh machine guards, which protect operators from moving parts while maintaining full visibility. These guards are essential for compliance with UK health and safety standards, particularly in factories and manufacturing facilities.

Custom designs enable tailored solutions that fit specific machinery, equipment layouts, and safety protocols. The material’s durability ensures long-term performance under heavy usage conditions.

Manufacturing Applications of Wire Mesh

The manufacturing sector benefits from the precision and reliability that wire mesh provides. Built to withstand demanding industrial processes, it plays a crucial role across various industries.

Filtration Systems

Wire mesh is used extensively in filtration processes, often appearing in chemical plants, food production lines, and wastewater treatment facilities. Its customisable weave ensures the perfect balance of filtration and flow, and stainless steel options provide excellent resistance to corrosion.

For instance, fine mesh grids are used in food manufacturing to separate particles while maintaining hygiene standards. Similarly, industries that handle corrosive substances rely on coated or galvanised wire mesh for long-lasting performance.

Material Handling

Wire mesh trays, baskets, and shelving systems support material handling and storage in manufacturing environments. These products provide durable solutions for transporting and storing goods while maintaining airflow and visibility.

Custom-designed wire mesh baskets are especially popular within the medical and food industries, where precise specifications are required to ensure hygiene and efficiency.

Supportive Structures

Wire mesh is a go-to material for reinforcing concrete within the construction aspects of manufacturing plants. Due to its strength, flexibility, and ease of installation, it ensures added stability for structures such as floors, walls, and columns.

The mesh’s adaptability also makes it an excellent fit for conveyor belts, sieves, and screens used in other manufacturing processes.

Key Benefits of Wire Mesh

Design Flexibility

Perhaps one of the greatest assets of wire mesh is its ability to be customised to any application. Whether you need large panels for infrastructure use or intricate designs for aesthetics, wire mesh can be tailored to meet precise project requirements.

With UK-based companies like Wire Mesh Fabs, bespoke orders can include specific hole sizes, material thickness, coatings, and panel dimensions, ensuring a perfect fit for every purpose.

Durability and Longevity

The durability of wire mesh outperforms many other materials. Resistant to environmental factors such as corrosion, UV exposure, and physical impact, it’s designed for long-term performance—even in extreme conditions.

Sustainability

Modern projects increasingly prioritise eco-friendly solutions. Wire mesh is highly recyclable, and its durability reduces waste over time. Sustainable materials like stainless steel align with green initiatives and long-term cost savings.

Why Choose Wire Mesh Fabs?

At Wire Mesh Fabs, we’ve been at the forefront of bespoke wire mesh fabrication since 1979. Based in the UK, our team specialises in creating innovative solutions for architectural, security, and manufacturing projects. We pride ourselves on using high-quality materials and advanced fabrication techniques to deliver results that exceed expectations.

Why Work With Us?

- Custom consultation and design services.

- Extensive experience across diverse industries.

- Top-rated customer satisfaction and reliable delivery.

Final Thoughts

From aesthetic marvels in architecture to vital safety applications and precision-driven manufacturing systems, wire mesh proves itself as one of the most versatile materials in modern design and industry. Its ability to balance functionality with style makes it a mainstay in projects across the UK.

If you’re ready to harness the versatility of wire mesh for your next project, contact Wire Mesh Fabs today. Our experts will help you turn your vision into reality, ensuring durable, bespoke solutions tailored to your specific needs.