Welded mesh is known for its strength, durability, and versatility, making it a popular material across a wide range of sectors. However, not all welded mesh panels are created equal, and choosing the most suitable type depends on a number of factors including material, wire diameter, aperture size, finish, and intended use.

In this guide, we’ll take a detailed look at how to choose the right welded mesh panels for your project and what you should consider before making a purchase.

What Are Welded Mesh Panels?

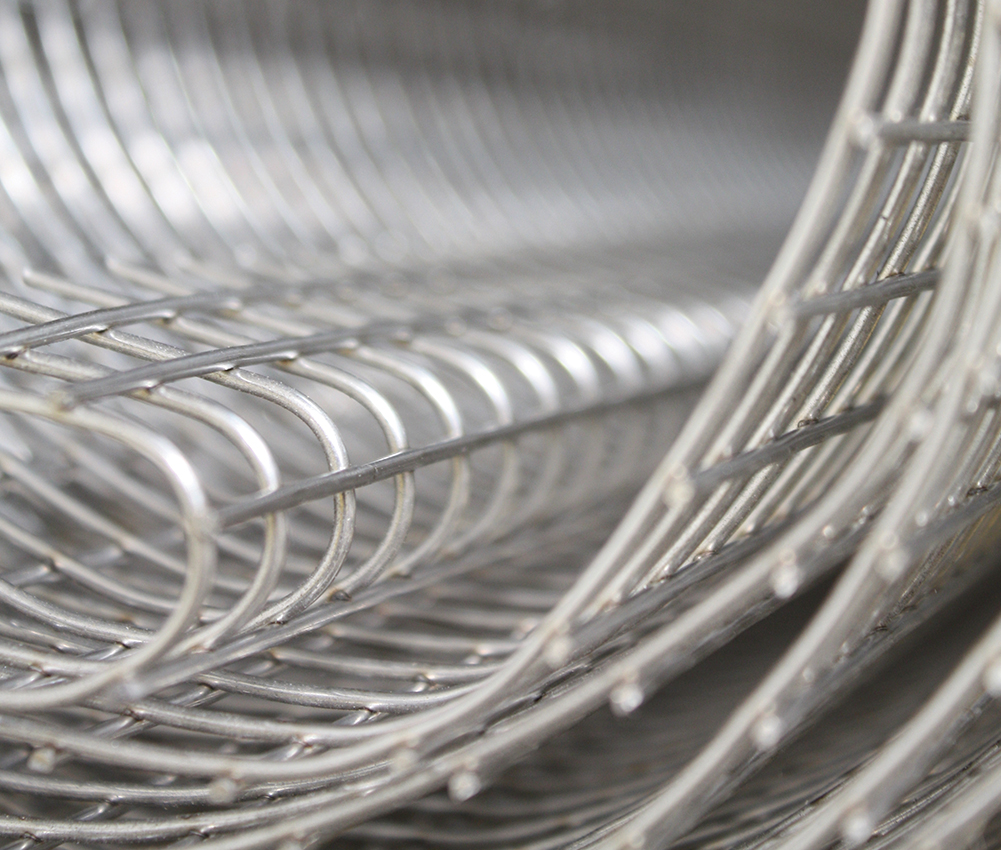

Welded mesh panels are made by welding vertical and horizontal wires at their intersections to form a rigid grid. This results in a strong, consistent pattern that holds its shape under stress. These panels are manufactured in a range of specifications and can be produced from mild steel, stainless steel, or galvanised wire, depending on the application requirements.

Unlike woven mesh, welded mesh is more stable and resistant to deformation, making it ideal for applications that demand strength and security.

Key Factors to Consider

1. Material Type

One of the most important choices is the type of metal used:

-

Mild Steel – Affordable and easy to work with, but prone to rust if not treated. Suitable for indoor or non-corrosive environments.

-

Galvanised Steel – Offers better corrosion resistance due to a protective zinc coating. Ideal for outdoor use or where moisture is present.

-

Stainless Steel – Highly durable and resistant to corrosion, even in harsh environments. Often used in food processing, chemical industries, or coastal applications.

Choose the material based on environmental exposure and the required lifespan of the mesh.

2. Wire Thickness (Gauge)

The thickness of the wire used in the mesh panel will directly impact its strength. Thicker wires (lower gauge numbers) provide greater rigidity and are suitable for heavy-duty applications such as security fencing, while thinner wires may be used for lighter applications like animal enclosures or garden trellising.

3. Aperture Size

Aperture refers to the distance between the wires, and it plays a crucial role in determining the mesh’s suitability:

-

Small Aperture – Useful for pest control, sieving, or applications where fine containment is needed.

-

Medium Aperture – Commonly used in cages, fencing, and shelving.

-

Large Aperture – Ideal for structural support or reinforcement applications.

Your choice will depend on what needs to pass through or be contained by the mesh.

4. Panel Size and Shape

Standard panels typically come in fixed sizes, but bespoke dimensions are often available. Consider the area you need to cover, whether the mesh will be cut to fit, and if prefabricated panels will save time and reduce waste.

Custom mesh fabrication services, such as those provided at Wire Mesh Fabrications, allow you to specify your required size, shape and design for a tailored solution.

5. Surface Finish

The surface treatment of your mesh panels can affect not only aesthetics but also corrosion resistance:

-

Self-Colour (Untreated) – Requires painting or powder coating for protection.

-

Pre-Galvanised or Hot-Dip Galvanised – Offers rust resistance and an industrial finish.

-

Powder Coated – Available in various colours, providing added protection and a more attractive finish.

-

Stainless Steel Finish – Naturally resistant to corrosion without additional coatings.

Common Applications of Welded Mesh Panels

Welded mesh is incredibly versatile and is used across numerous sectors, including:

-

Construction – For concrete reinforcement, wall retention, or safety guards.

-

Agriculture – As fencing for livestock, chicken coops, or crop protection.

-

Security – In fencing, window grilles, or cages.

-

Architecture – As balustrades, cladding, or decorative features.

-

Industrial – Machine guards, storage cages, and partitioning.

Understanding the intended application will help determine the correct strength, finish, and aperture size for the panel.

Why Choose Wire Mesh Fabrications?

At Wire Mesh Fabrications, we supply high-quality welded mesh panels that are manufactured to suit your specifications. Whether you need standard panels or bespoke solutions, our team can help guide you to the right product based on your project’s requirements.

We offer:

-

Expert advice and technical support

-

A wide range of stock and made-to-order options

-

Custom finishes and panel sizes

-

Fast and reliable UK delivery

With years of experience in supplying to sectors such as construction, agriculture, transport and design, we are proud to be a trusted name in welded mesh manufacturing.

Final Thoughts

Choosing the right welded mesh panel isn’t just about picking something off the shelf – it’s about matching the correct specifications to your application. By considering factors like material, wire thickness, aperture, finish and size, you can ensure that your mesh performs reliably and lasts for years.

If you’re unsure which welded mesh panel is best for your project, our friendly and knowledgeable team is here to help. Explore our range of products here or get in touch today for bespoke support tailored to your needs.